A Closer Look

When I first saw the clam shell packaging that the Verticool III heat sink comes in, I thought that I had gotten a used sample, but it was in fact new.

All of the Spire Verticool III heat sinks have been taped to keep everything where it should be. Heat sealing would have been a little more attractive, but that of course adds some cost.

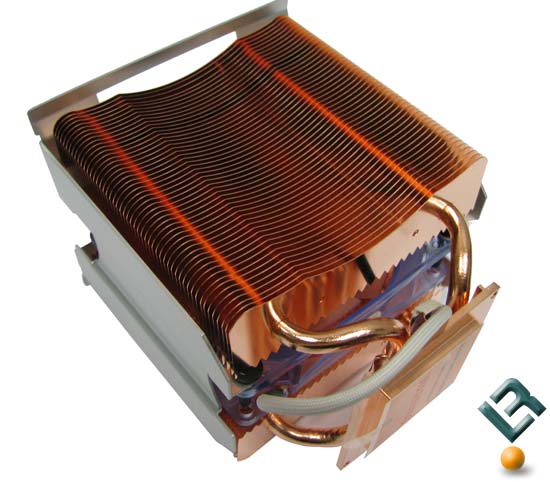

Like the previous Verticool coolers the Verticool III has a 90mm fan, but this time Spire has moved the fan to the center of the cooler. On either side of the fan is a row of ~50 copper fins on two heat pipes. Wrapped around the cooling towers is an air shroud; it covers the sides to aid in directing airflow through the cooler and not out the side. This shroud also acts as the fan mount.

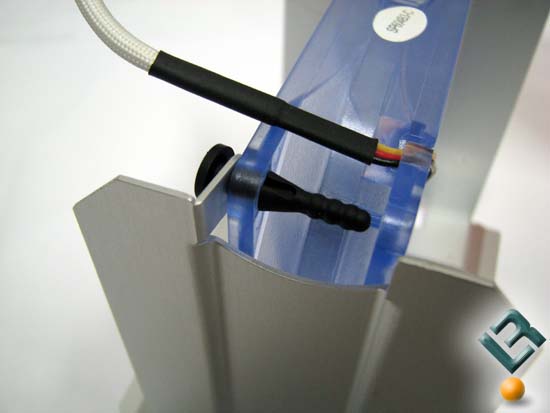

The fan is mounted via four rubber screws into the shroud. This is a nice touch as it will absorb the vibrations from the fan, thus cutting down on noise.

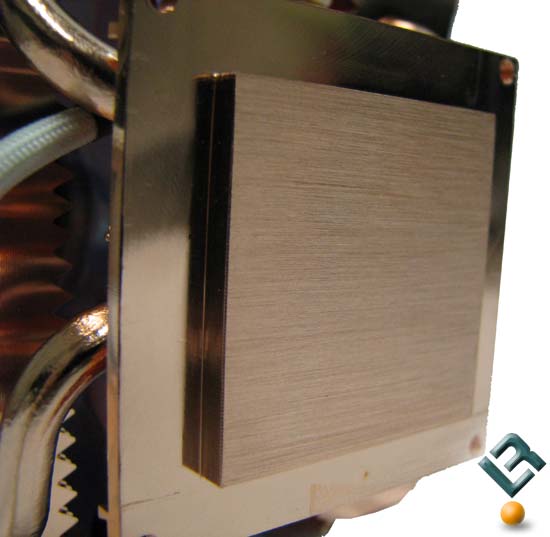

The all copper base comes protected with a protective plastic film, once remove we can see the surface of the base. All tough it does not have a mirror finish, it feels smooth. Little bit of elbow grease and some 2000 grit sand paper will shine it right up. For our purposes today weĄŻll leave it be.

For mounting the cooler Spire includes all the mounting hardware and backing plates one would need to mount this cooler on a AMD socket 754 / 949 / 939 procrssors as well as Intel LGA 775 processors. Also included in the kit is a fan controller mounted in an expansion slot cover, a small tube of thermal grease (0.5g of Stars-420 white grease), and the all important instructions. It should be noted that the thermal grease will begin to function at its optimum potential, after a gradual increase in heat-dissipation. This happens approximately 168 hours (7days) after initial application on the Stars-420 thremal grease that Spire is using.